Breaking, Shrinking, Swelling, Smelling. Strips, Jars & Cigars…

As part of our first-of-its-kind CobBauge house, our team has been learning about the earth field tests for CobBauge buildings!

With the support of our European and UK partners, this has involved completing more than 10 different in-house tests on two types of local earth material sourced in Norfolk: one from a quarry in Kings Lynn and the other from a quarry in Bilney. These tests were important to investigate the clay content and overall qualities & characteristics of the materials; allowing us to assess whether they would be suitable to be used for our CobBauge walls.

While they may not be the most visually beautiful to record, clean & tidy to perform, nor elegantly named (Squash Test, Smell Test, Cigar Test, Jar Test, Strip Test, Disc Test, Pool Test etc.) they have been extremely interesting and fun to complete.

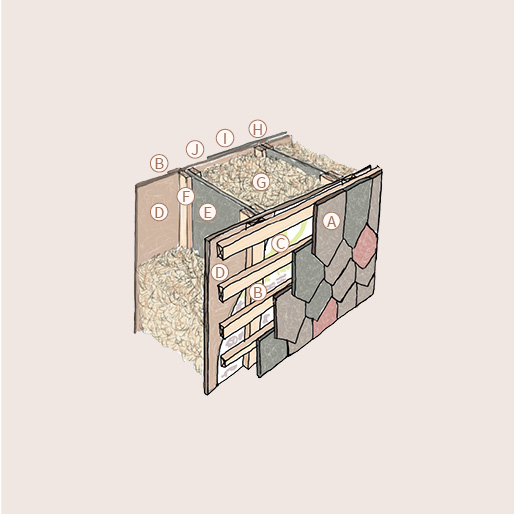

From these tests we were hoping to find a material that would be suitable for the ‘light earth mix’ (the insulating external face of the CobBauge wall), which requires a high clay content and a small particle grading of predominately fine sand and silt. In addition to sourcing a material that would be suitable for the ‘cob mix’, (the load bearing inner face of the wall) which needs to have a lower clay content, of below 20%, and a wider grading range. The following explains three examples of our tests that we completed.

The Observation Test

This initial simple yet effective test finds out the general characteristics and qualities of the clay: colour, consistency, texture, presence of aggregates and their size and type. From this we could see that the orange-brown Bilney material had a crumbly consistency, gritty texture and contained a range of different types of aggregates and of different grades (particle sizes).

Whereas the blue-grey Kings Lynn material had a compact consistency, smooth texture and contained no visual range of aggregate types or grades; it looks to have a consistent small particle size.

From this, we could instantly make the presumption that both materials contained clay, due to the way that the material stuck together, whilst the Bilney material contained a higher grading range than the Kings Lynn. Therefore; we decided to proceed with testing both materials. This shows the importance of this simple test.

The Cigar Test

The Cigar Test clearly demonstrated that the Kings Lynn material was more clay rich than the Bilney. This test involved rolling the material into a long cylinder by hand on the table and then slowly pushing the end of the cigar off the table until it broke. The broken off piece was then measured, and its length indicated the clay content: less than 5cm and the material has very little clay, a range of 10-20cm indicates that it could be used for a cob mix in its current state, and above 20cm means that the material is clay rich and therefore could be used for the Light earth mix. Our results found that the Bilney material averaged a breakage length of 24.3cm, which is close to the cob mix range, while the Kings Lynn clay’s average length was considerably longer of 66.9cm, showing that it has a high clay content and adhesive properties, making it suitable for the light earth mix.

The Shrinkage Test

This test involved filling a wooden shrinkage box with the material, leaving it to dry out and then measuring the length of the material to calculate the linear shrinkage percentage. As the higher the shrinkage, the more fine soil, silt and clay that is likely to be present, this test confirmed that the Kings Lynn Clay contains a higher clay content than the Bilney as it had a higher linear shrinkage percentage of 9.4% compared to 5.6%.

Overall, these earth field tests confirmed that both materials had potential to be used for our CobBauge walls. The Bilney material being more appropriate for the cob mix due to its large grading range, lower clay content and therefore smaller shrinkage. Whilst the Kings Lynn material was more suitable for the light-earth mix due to its lack of aggregate, high clay content & adhesive properties. These materials have since undergone laboratory analysis by geologists to form a more technical and detailed understanding.

This testing process has been a great opportunity to develop in-house knowledge and understanding, through a hands-on experience, of the clay and processes involved in creating a successful CobBauge wall.

It is fantastic to work, share knowledge, project results and gain feedback with a team of partners in the UK & in France as part of this Interreg FCE Project. As May is the month for Europe, we feel the CobBauge project perfectly showcases the benefits of cross-border activities, between the UK & France to progress low-carbon building material research and development.

#UnifiedByTheChannel

Words by Katey Oven, Architectural Assistant.